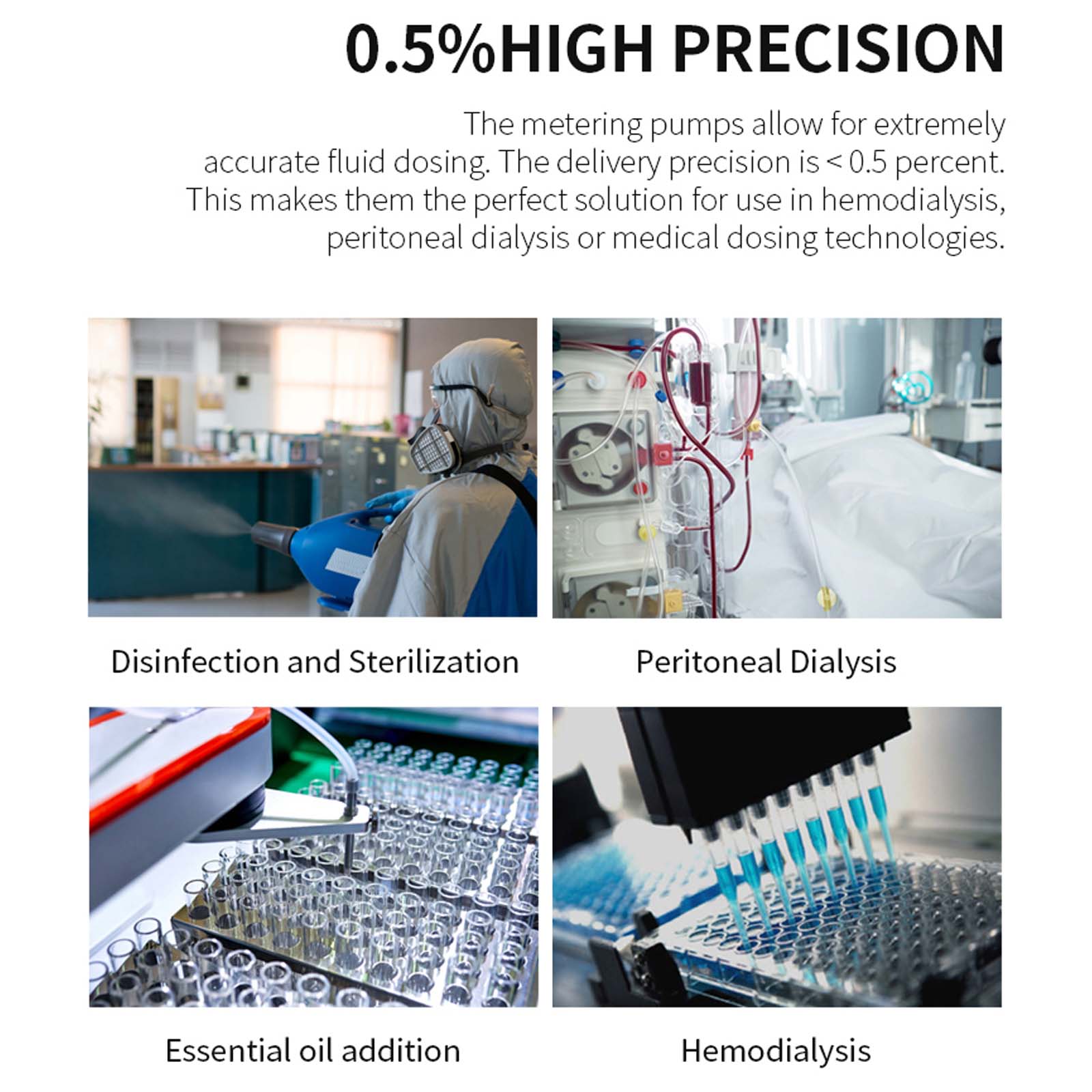

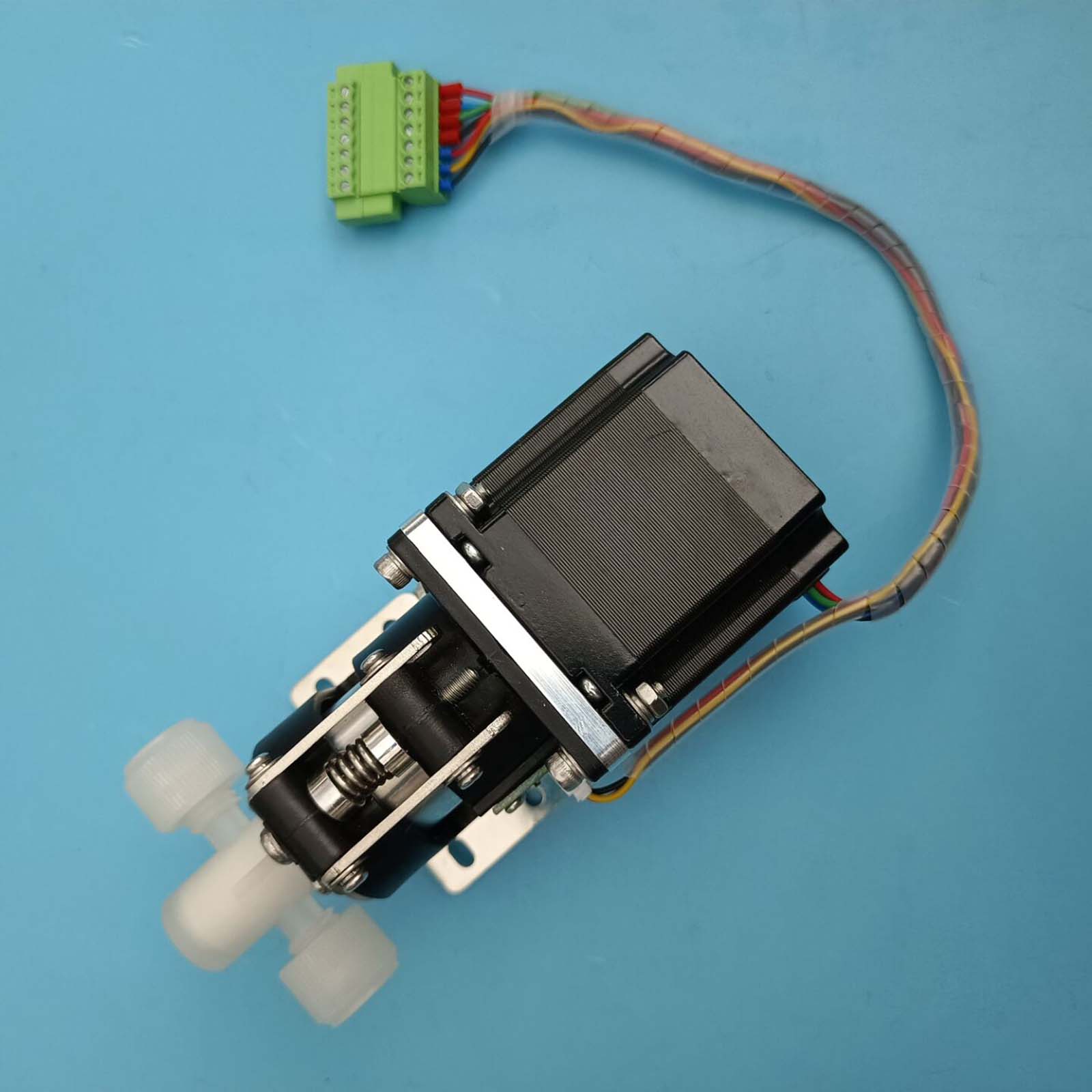

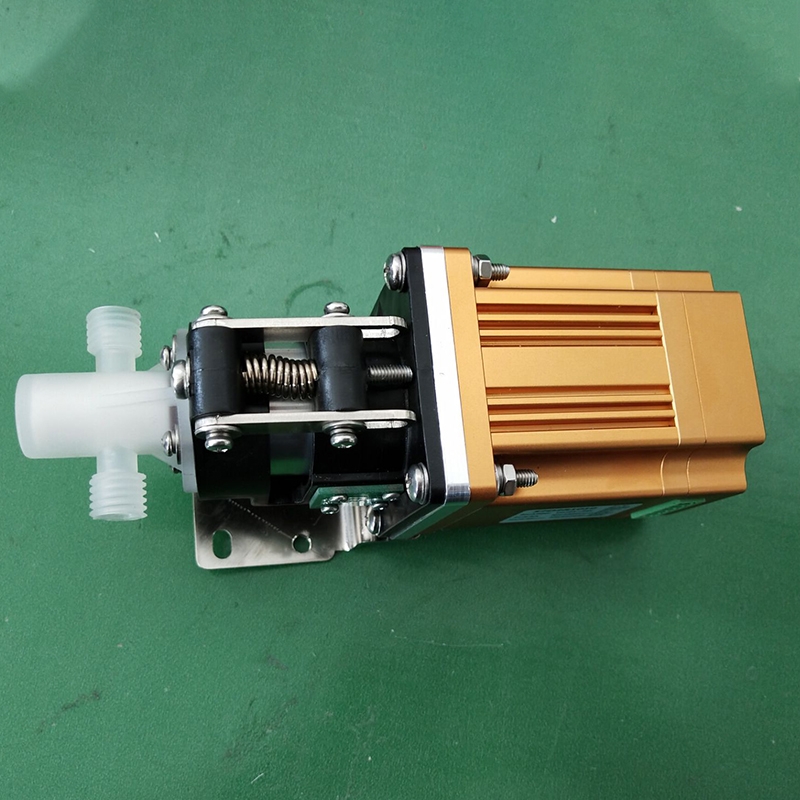

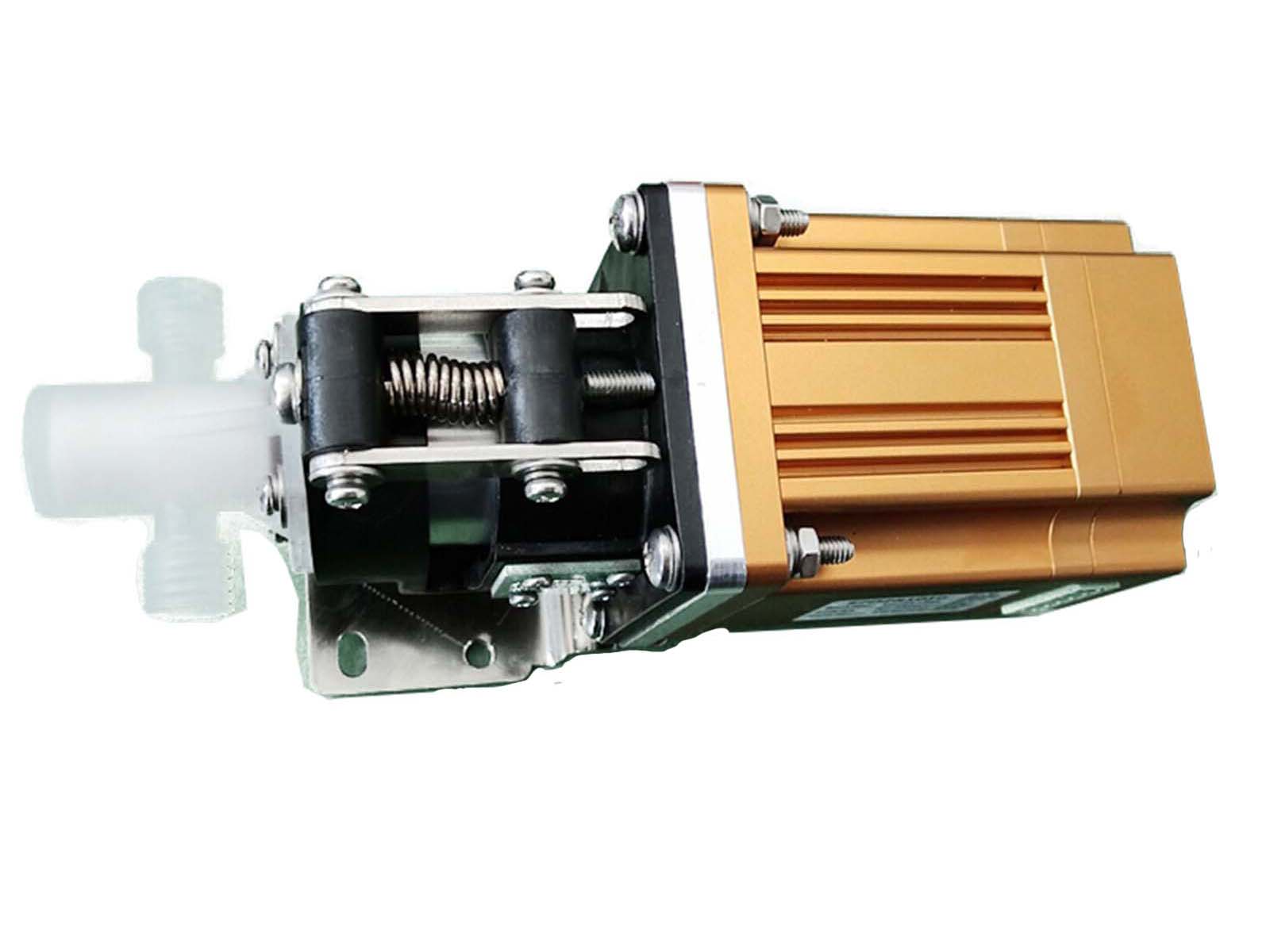

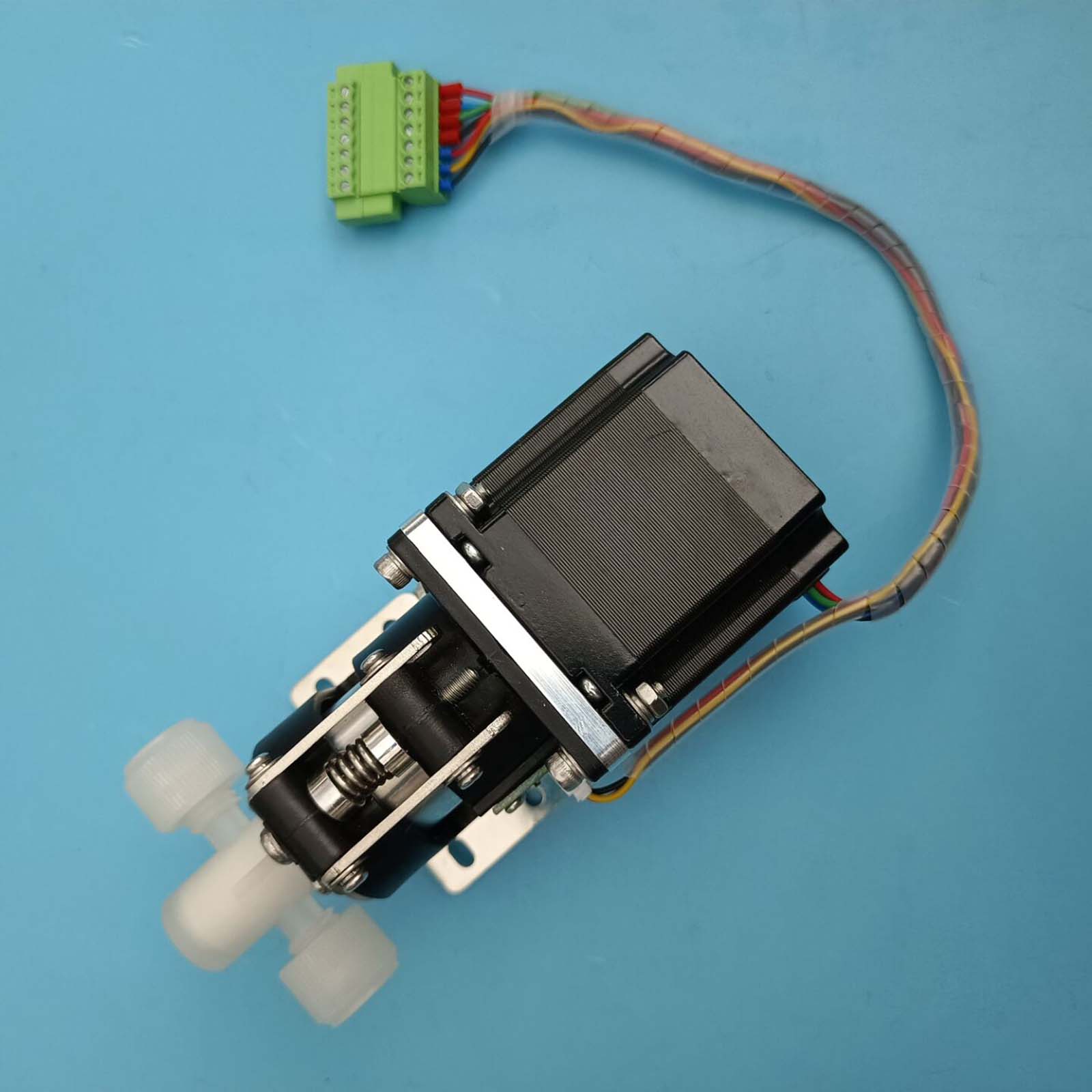

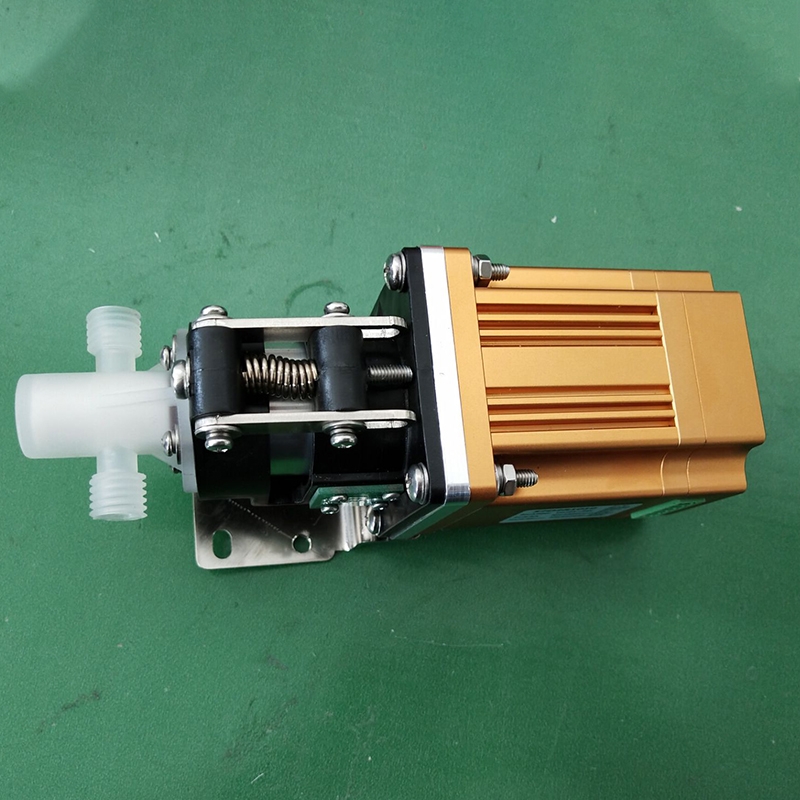

CP series rotary ceramic plunger pump is a kind of micro plunger pump with our own patented technology. It is precisely matched with ceramic outer shell and ceramic inner rod,

and performs reciprocating and rotating motion to realize the operation and delivery of liquid flow; , high temperature resistance, not easy to wear and other characteristics,

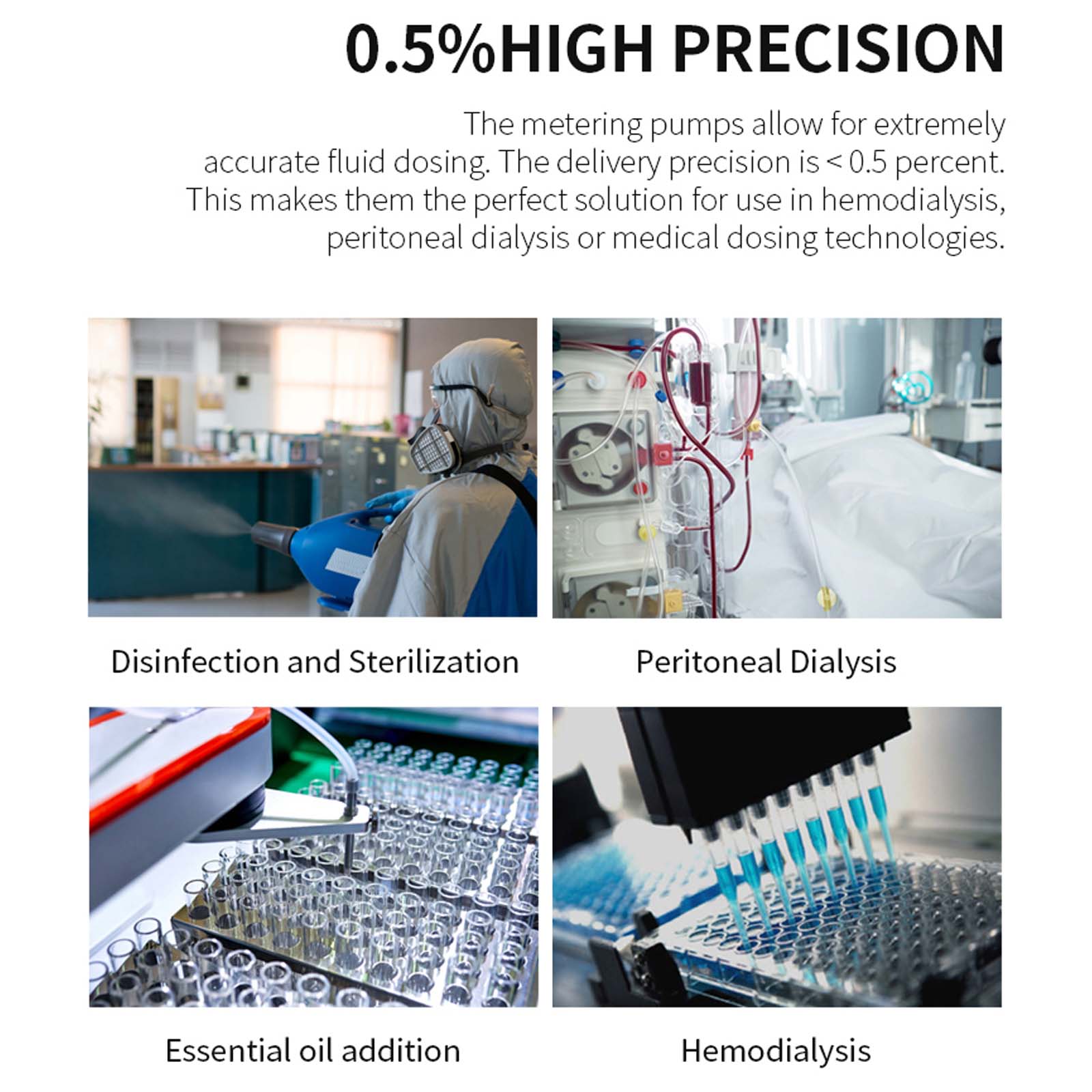

it is widely used in medical, chemical, scientific research, food processing and other industries.

Technical parameters:

1. Rated pressure: ≥0.2MPa

2. Flow: 0-20ml/min (adjustable), repeatability: ≤0.2%

3. Voltage: DC 24V, Power: 12W

4. Working temperature ≤100℃

5. Use medium: acid, alkali, salt, organic solvent, oil at room temperature

6. Driving mode: stepping motor, stepping angle 1.8°

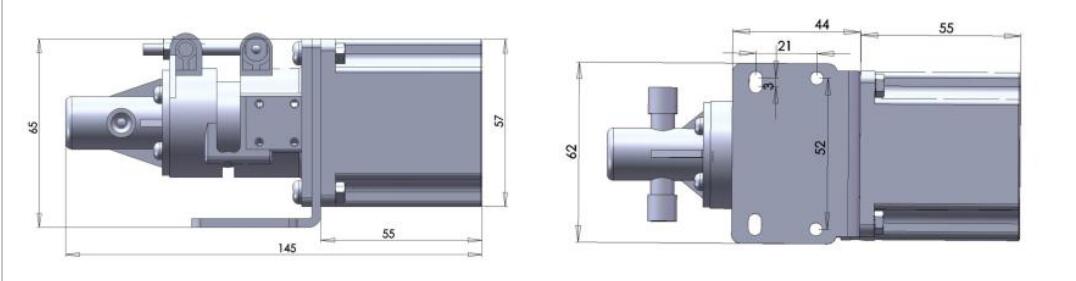

7. Installation size: 145mm×65mm×57mm

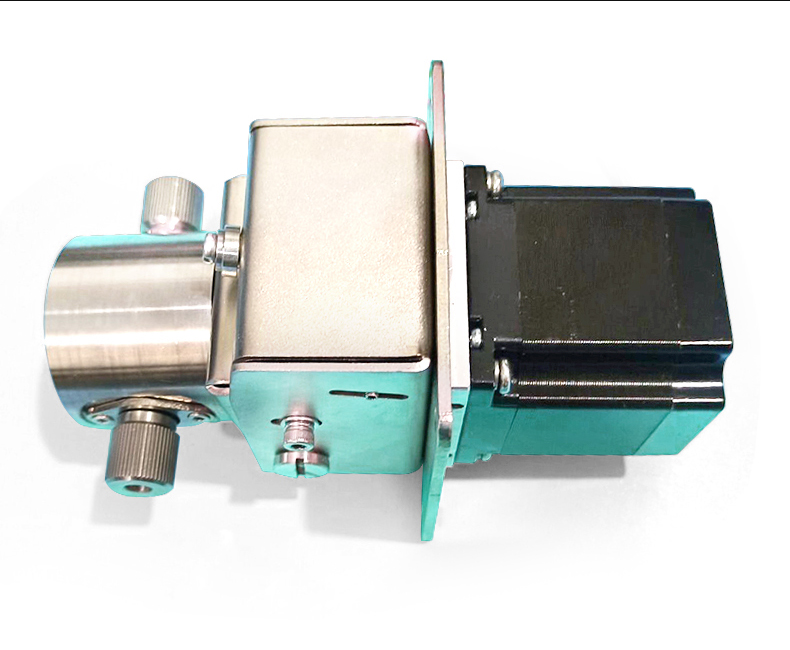

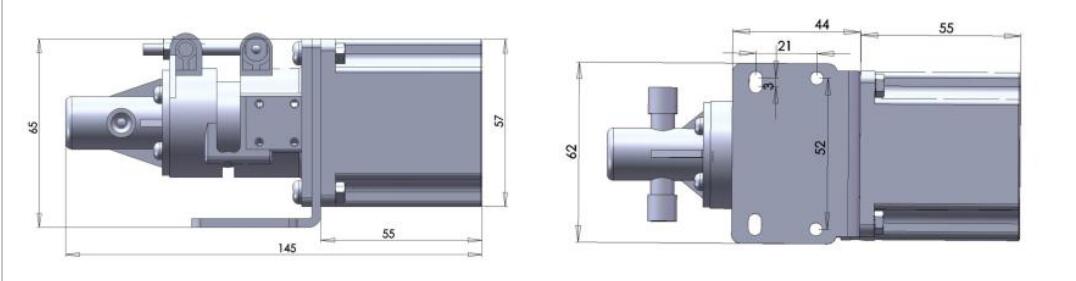

Structure and installation dimensions

In order to obtain high flow accuracy, please install the product vertically as

shown in the figure, and select the end of the fluid inlet lower than the outlet.

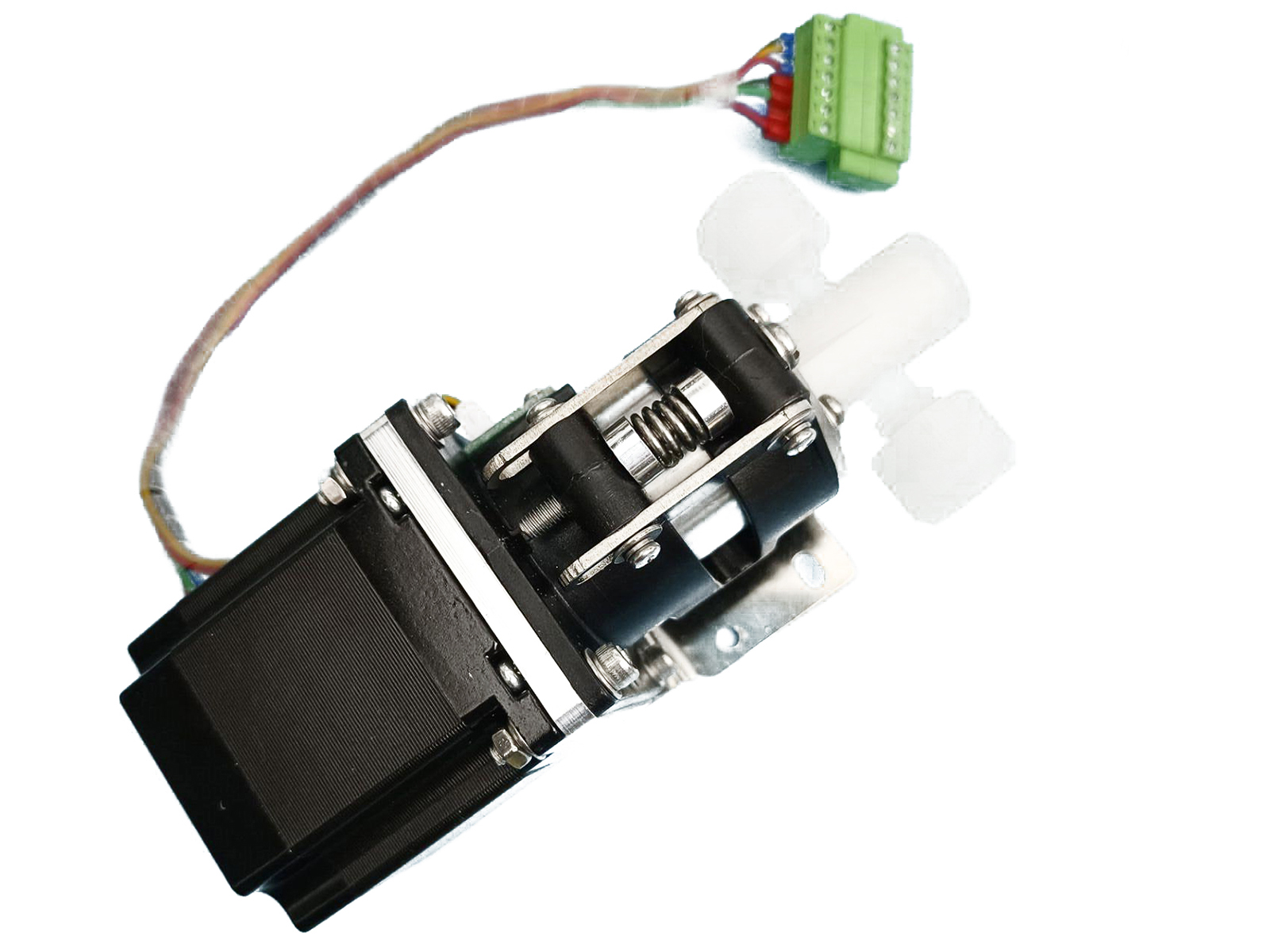

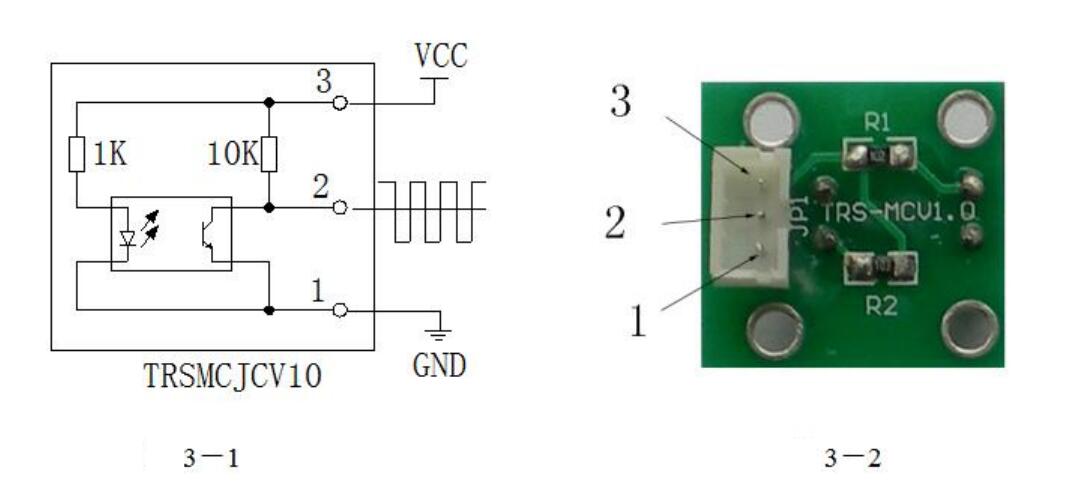

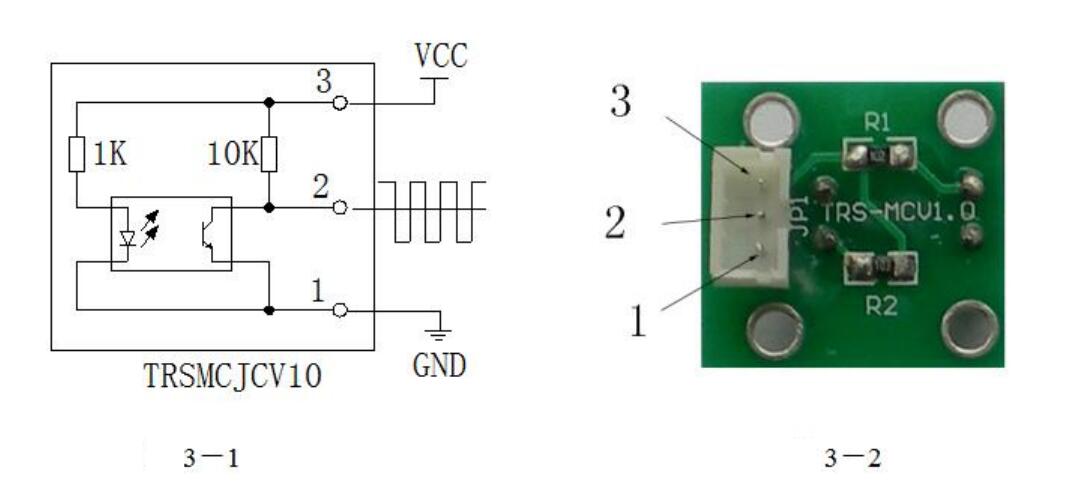

Speed feedback or position detection

CP series rotary ceramic plunger pumps are equipped with speed

measurement feedback or position detection signal board, VCC=+5V as

shown in the figure:

The tachometer turntable configured by the user for speed measurement

feedback can detect 10 pulses per revolution

The turntable configured by the user for the detection of the starting position of

the suction, detects one pulse per revolution,

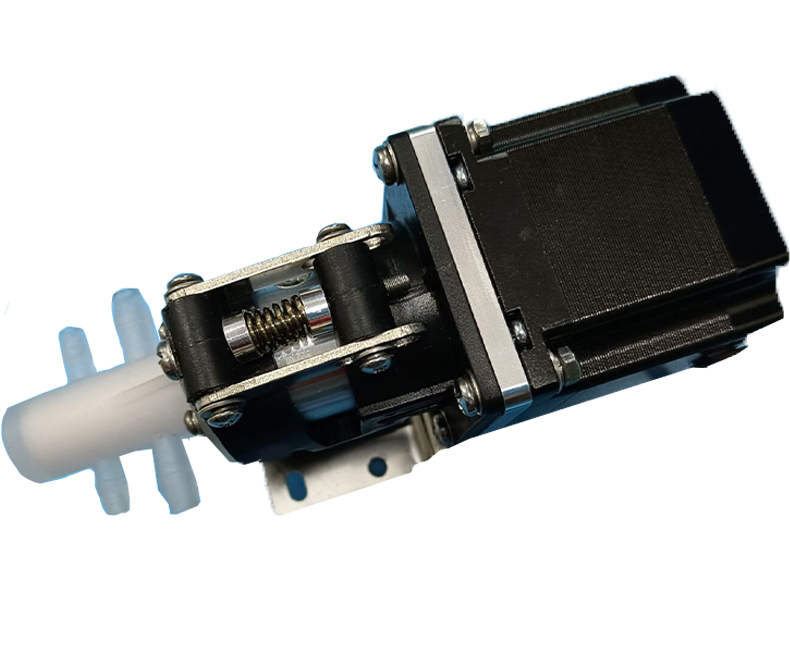

Driver (optional)

TRS series rotary ceramic plunger pump adopts the latest 32-bit DSP

technology stepper motor driver, the user can set any subdivision within 512

and any current value within the rated current, which can meet the application

needs of most occasions. Due to the built-in micro-segmentation technology,

even under low-segmentation conditions, it can achieve the effect of

high-segmentation, low, medium and high-speed operation is very stable, and

the noise is ultra-low. The driver integrates the parameter automatic tuning

function, which can automatically generate the optimal operating parameters

for different motors and maximize the performance of the motor.

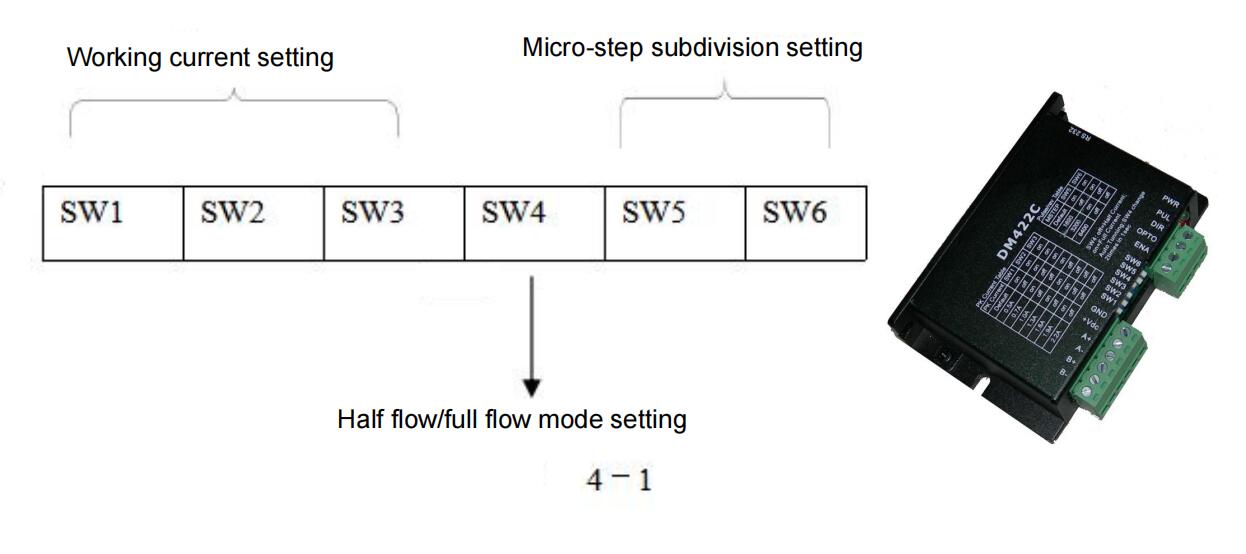

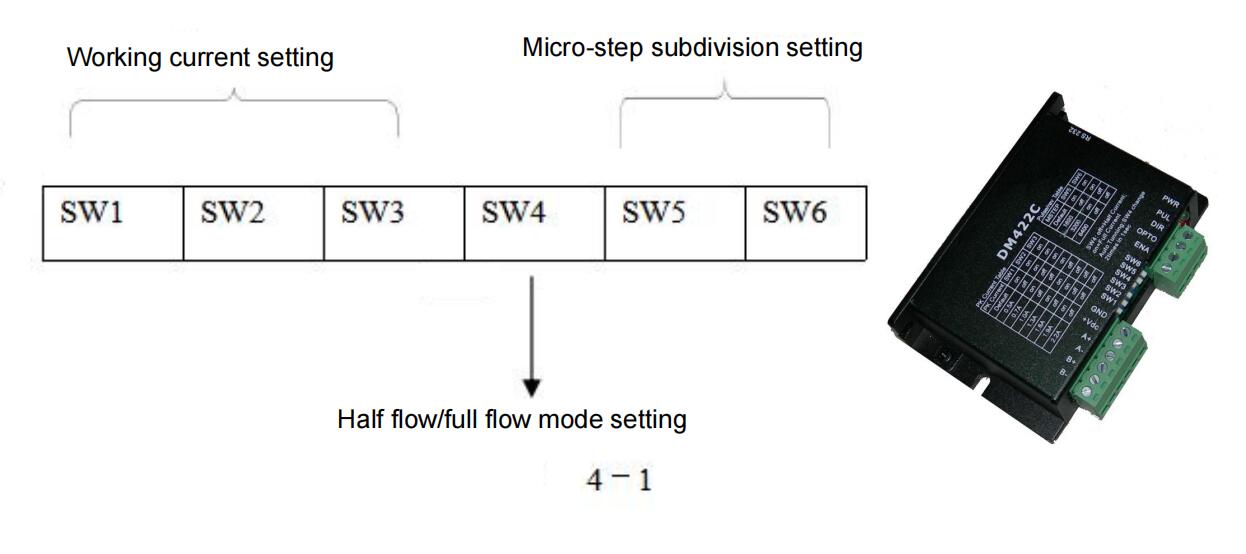

1. Driver function description

The DM422C driver uses a six-position DIP switch to set the subdivision

accuracy, dynamic current and half current/full current. The detailed

description is as follows:

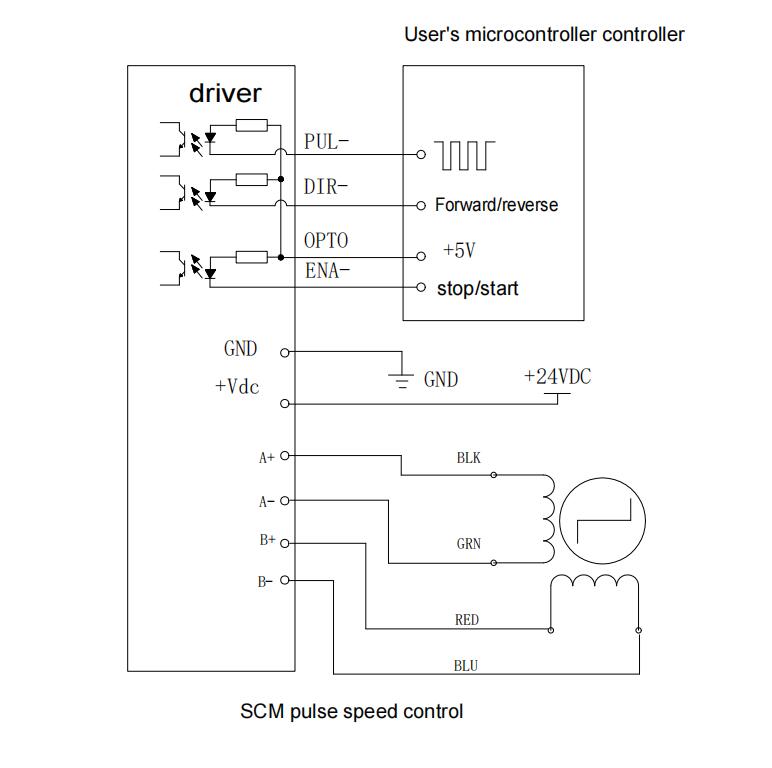

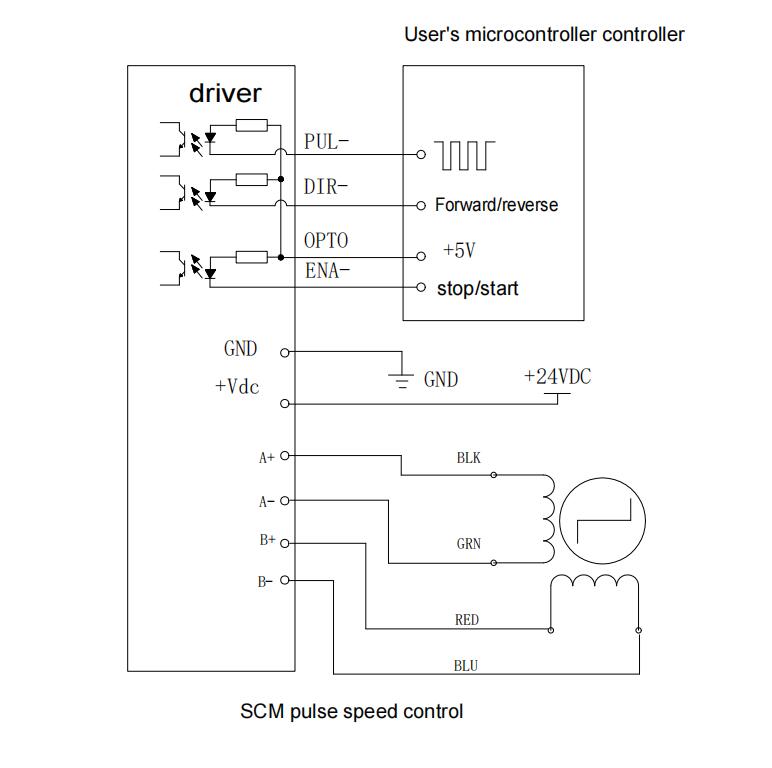

SCM pulse control mode

When the control signal voltage provided by the controller is greater than 5V,

the signal line needs to be connected in series with a current limiting resistor.

When the control signal voltage is 12V, a 1K 1/4W resistor needs to be

connected in series; when the control signal voltage is 24V, a 2K 1/4 resistor

needs to be connected in series.

In order to avoid malfunction and deviation, PUL, DIR and ENA should meet

certain control timing requirements, as shown in the following figure: