Gas Mass Flow Meter And Vacuum Gauge Are Used In Vacuum Coating Industry

Consultation email:

sales01@cxflowmeter.com

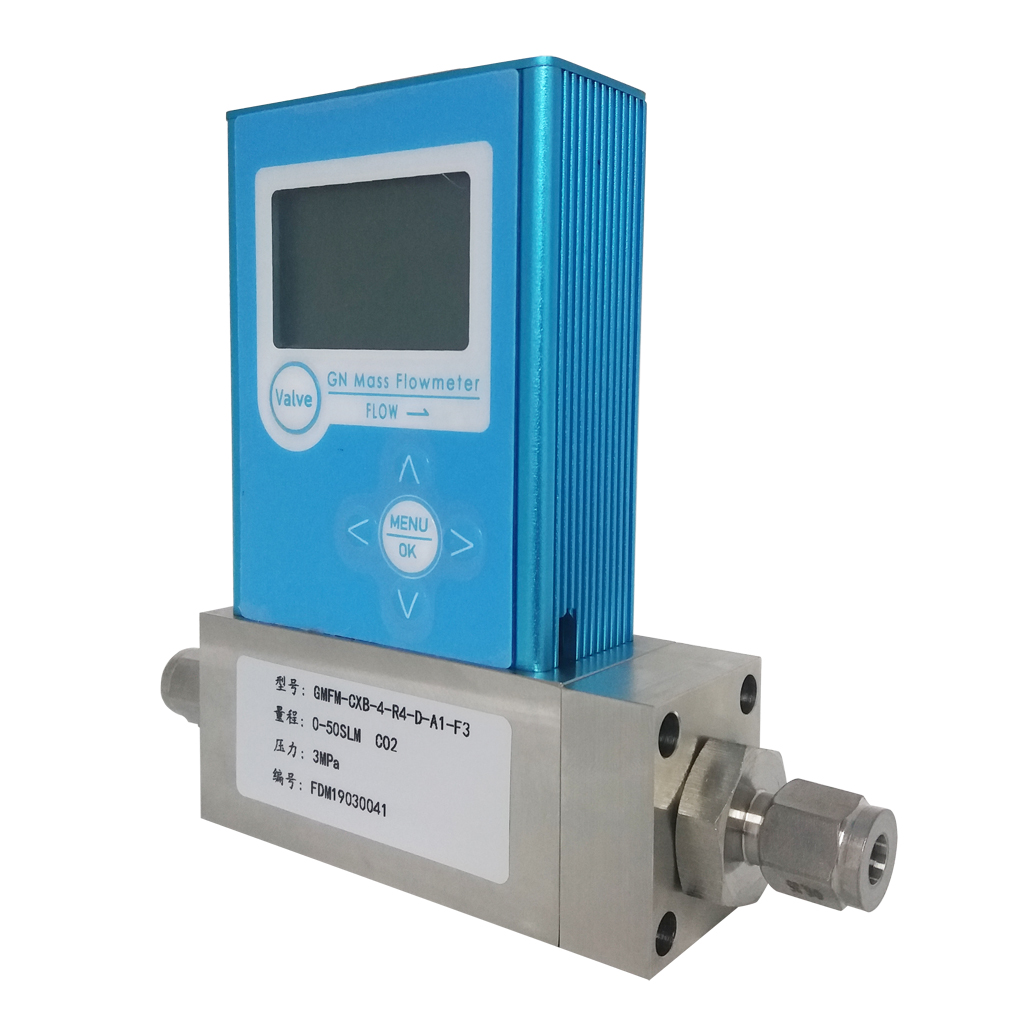

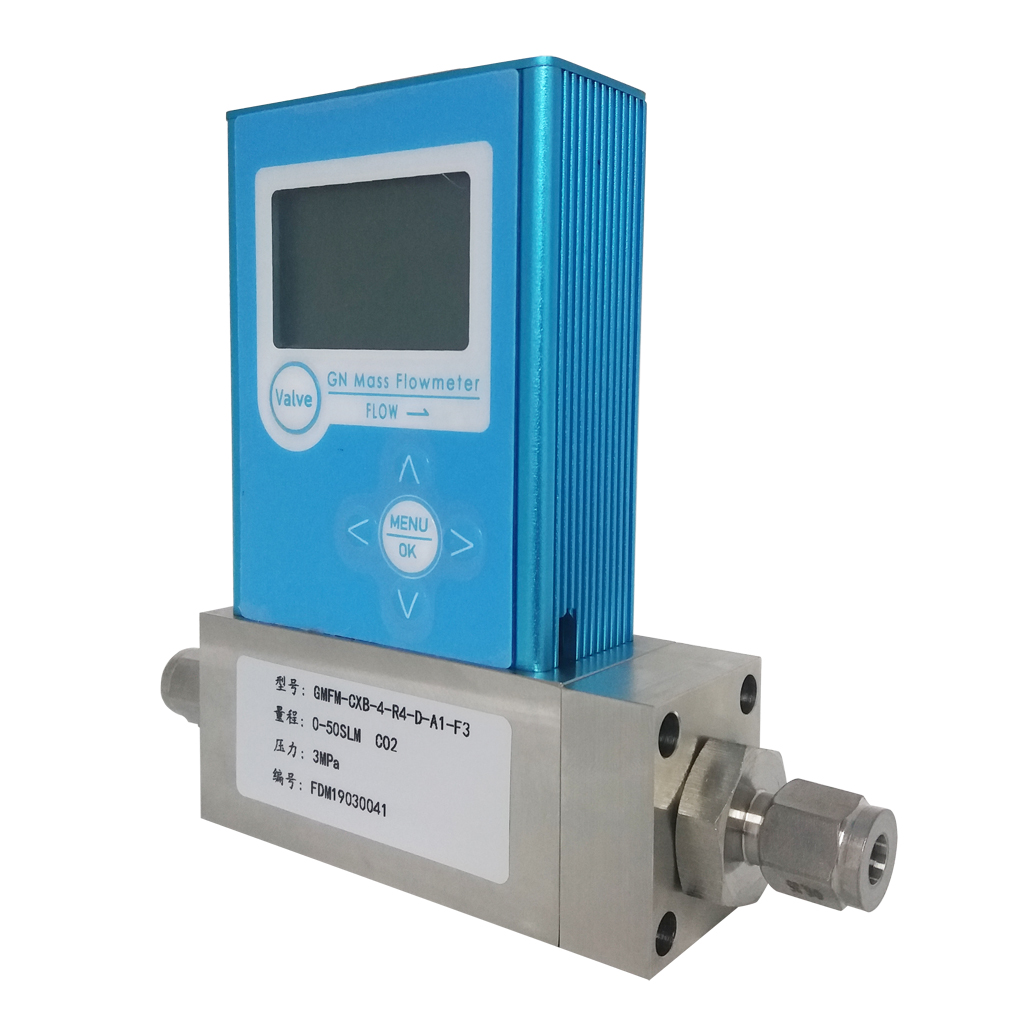

gas mass flow meter is used in vacuum coating industry

Vacuum coating: In the coating industry, there are mobile phone shells, faucets, panels, etc. with a thin layer of film on them.

Gas mass flow meters are mainly used for powder feeding and air blowing.

For example, there is a layer of gold powder and protective gas on the mobile phone shell. When coating the film, the gold powder needs to be

sent to the metal surface. (When the powder is fed, the conventional gas is air or nitrogen, or it may be gas, sometimes other gas is needed.

It has a color reaction with the powder, etc.), and the working environment is high temperature when it is attached. At this time, it is also necessary to

blow nitrogen or argon at the same time to prevent oxidation. At this time, a gas quality controller is also needed to control the amount of argon.

The coating must be vacuumed. Only in the case of vacuum, the coating will not react with other gases in the air. The pressure is basically a negative pressure state.

4 to 6 controllers are used on a coating machine, sometimes up to 12 controllers.

Note: Vacuum pressure gauge can also be used in vacuum coating industry

vacuum gauge

Gas mass flow meter and vacuum gauge are used together. The vacuum gauge has a very low control range, which can control the extremely

high vacuum condition of the coating chamber. To

The vacuum gauge can realize fast control, mainly based on the 0~10V linearity provided by the Pirani vacuum gauge sensor. In the above application,

the 0~10V signal corresponds to the extremely high vacuum of 0~0.5Torr. The flow controller uses this signal provided by the vacuum gauge to accurately

control the extremely high vacuum condition of the coating chamber.

Through local analog signal or RS232 communication, the set point of the controller can be easily set. To

The mass flow meter upstream of the vacuum controller is not affected by the downstream vacuum, and can accurately measure the mass flow,

volume flow, and cumulative mass of the gas flowing into the vacuum chamber.

If you want to know more about the parameters and prices of different models of our CIXI

gas mass flow meters and

vacuum meters, please consult

winny:

sales01@cxflowmeter.com