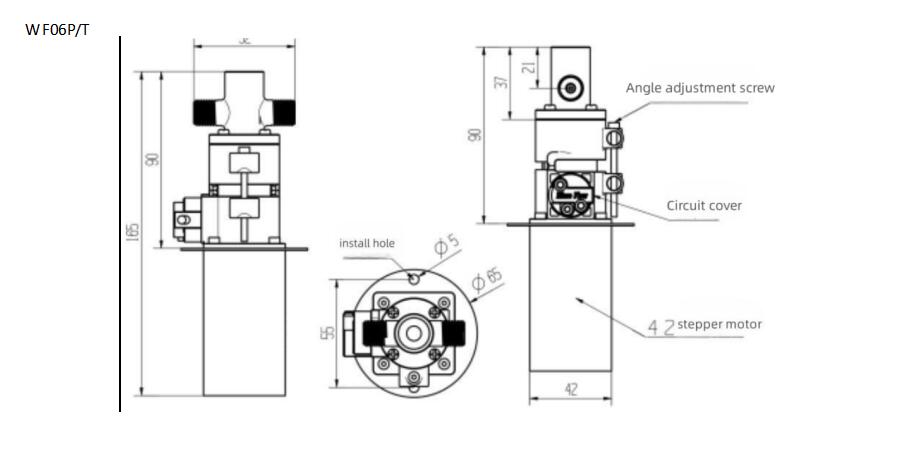

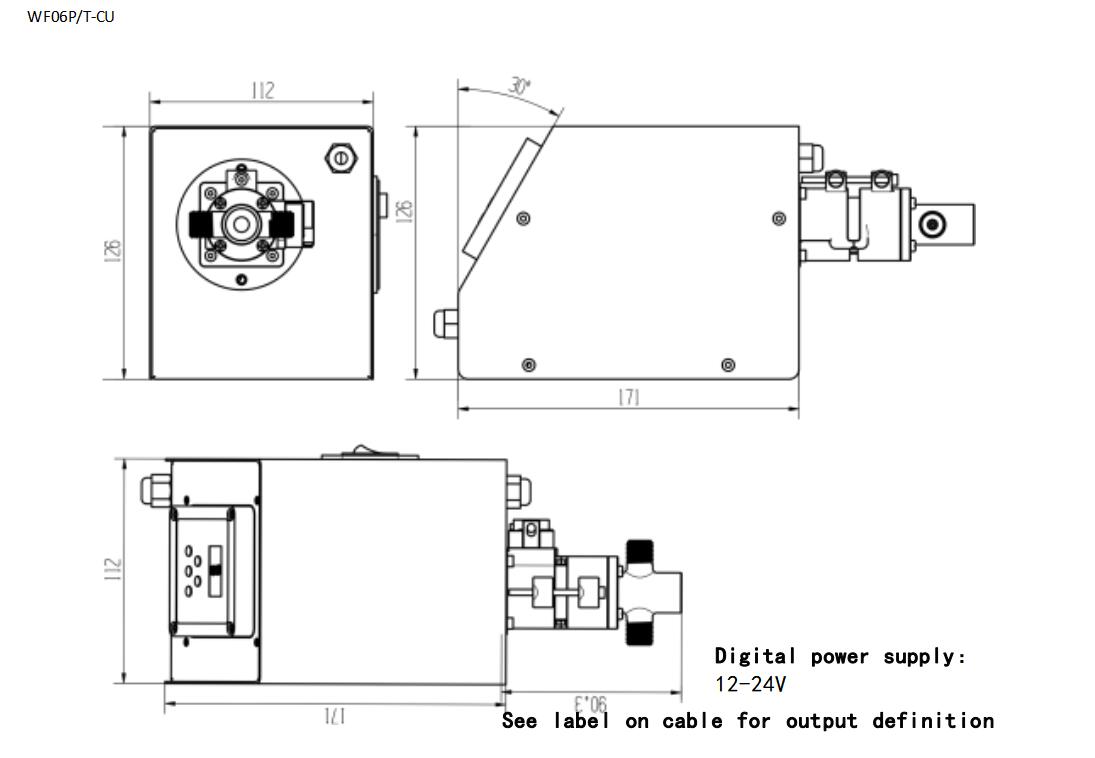

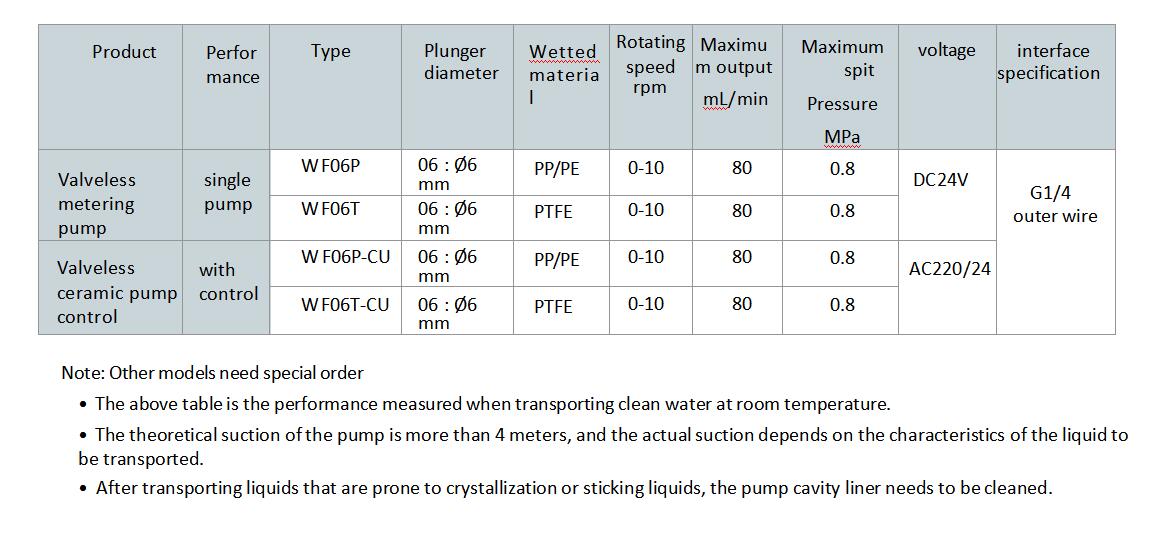

The process pump liquid can be precisely adjusted to 0.01ml/min, the quantitative filling can be adjusted to 0.1ml each time,

the speed is 0-10RPM, the maximum discharge volume is 80mL/min, and the maximum discharge pressure is 0.8MPA.

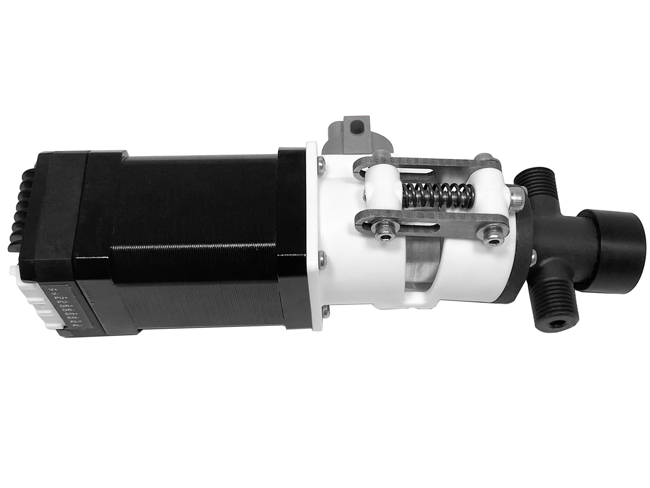

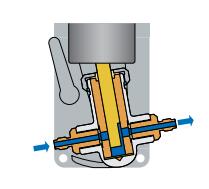

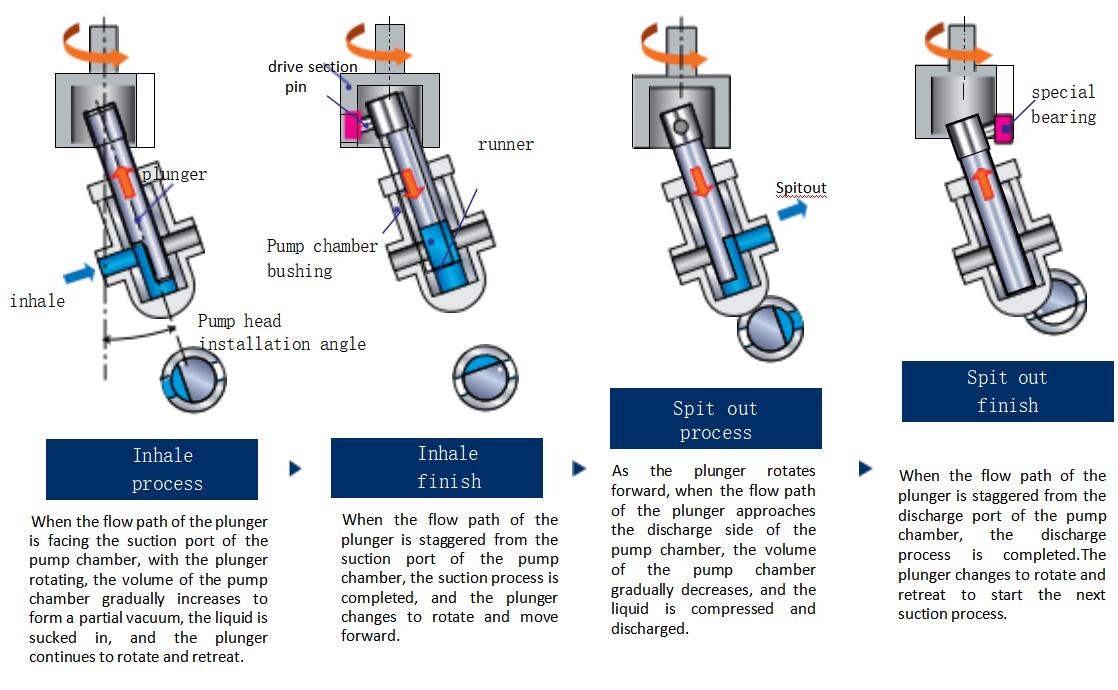

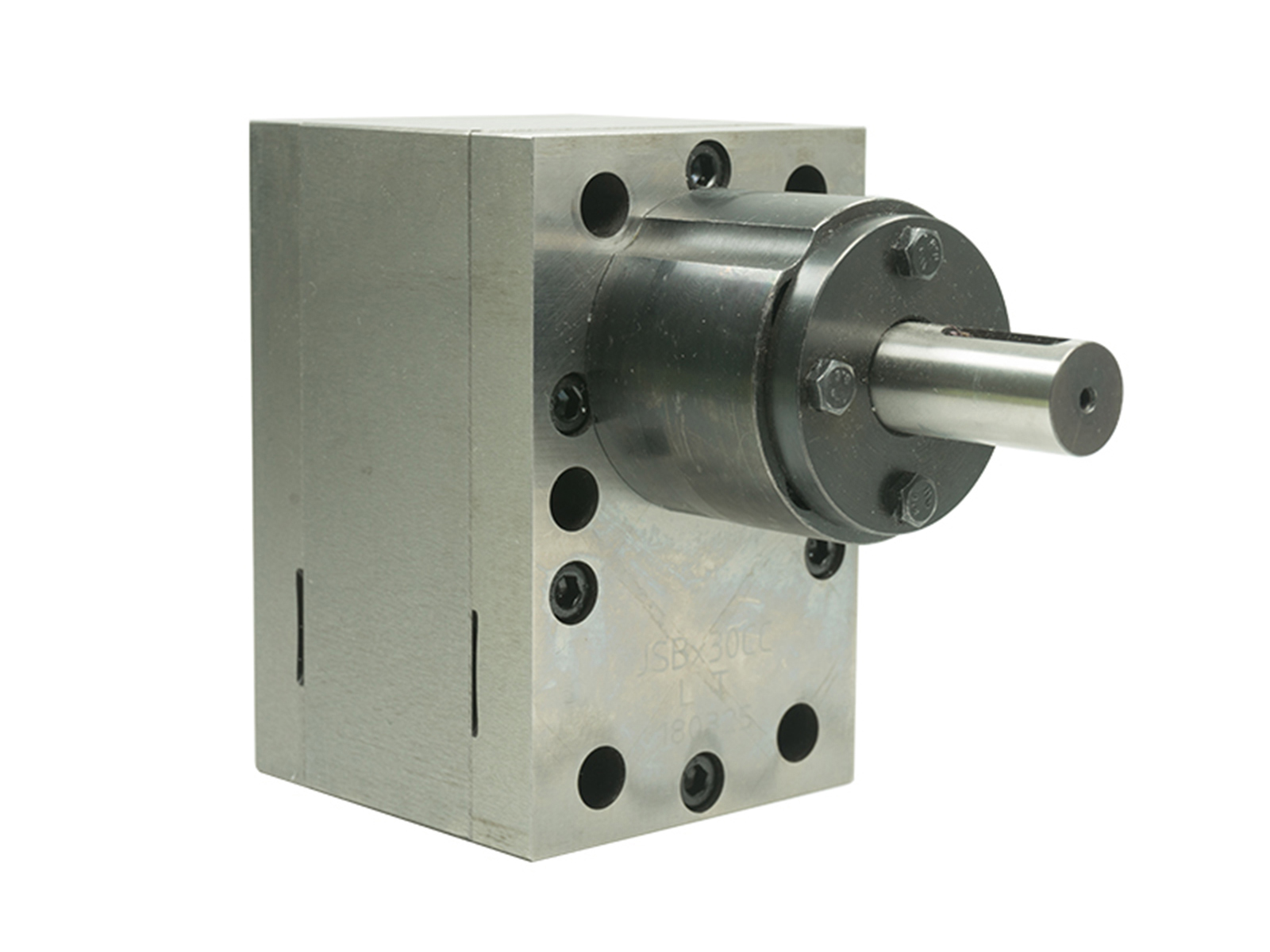

The small metering pump adopts high-quality fine ceramic plunger and unique valveless structure, which effectively solves the

common problems of general metering pumps such as blockage and seizure. The processing accuracy of the main parts reaches

the micron level, and ultra-high spouting accuracy can be obtained. Widely used in micro-precise injection of liquid medicine,

and delivery of various high-viscosity liquids.

Valveless pump process pump fluid: 0.1ml/min, 0.5ml/min, 1ml/min, 5ml/min, 10ml/min, 20ml/min, 30ml/min, 40ml/min, 50ml/min min, 60ml/min, 70ml/min, 80ml/min

Valveless pump quantitative filling (0.1ml/time, 0.5ml/time, 1ml/time, 3ml/time, 5ml/time, 10ml/time)

Pump displacement adjustment 0-0.13ml/r