mag flow meter installation guidelines

Email:sales01@cxflowmeter.com

mag flow meter installation guidelines

An

electromagnetic flow meter is an instrument used to measure the flow of conductive liquids and slurries in closed pipes below 5 microsiemens (Siemens: unit of conductivity).

Its performance is not affected by properties such as corrosiveness, viscosity, pressure, density, acidity and alkalinity of the medium. It can measure the flow of liquids, pastes

and slurries in industries such as water, wastewater, chemicals, fertilizers, dairy, food, beverage, pharmaceutical, medical, petrochemical, paper, mining and agriculture. It is also

commonly used to measure steel plants and power plants. of cooling water flow.

2. Installation Guide

1.

Mag flow meter must be installed in a location free of interfering components (valves, T-tubes, elbows, pumps, etc.). To ensure there is no turbulent laminar

flow upstream of the electromagnetic flowmeter. Therefore, the electromagnetic flowmeter must be installed in a straight pipe at a distance of at least 3xDN from upstream interfering

components and at least 2xDN from downstream interfering components.

IMPORTANT: If there is a valve in the pipeline, the electromagnetic flowmeter should always be installed on the downstream side of the valve

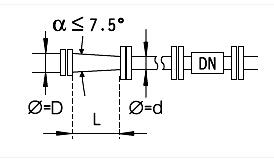

2. If reducing joints are required, the internal angle shall not exceed 7.5°. The minimum length to keep the angle below 7.5° can be calculated by the following formula:

L = (D - d) x 7.63

Among them, "D" is the major diameter of the reducing joint, and "d" is the minor diameter of the reducing joint.

For example: If an electromagnetic flowmeter with a pipe diameter of DN80 is installed downstream of a 100mm pipe, the length of the reducing joint must be at least 152.6mm to

keep the internal angle below 7.5°.

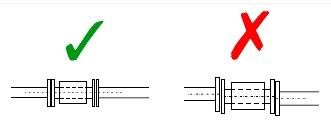

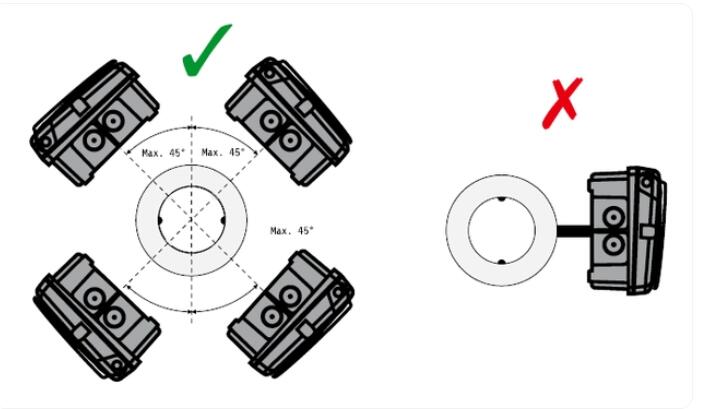

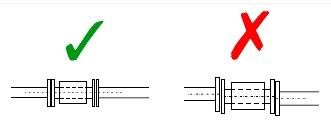

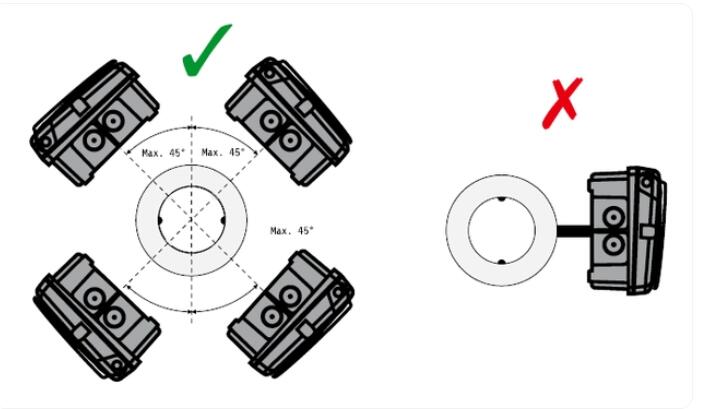

3. The flange connection of the electromagnetic flowmeter must be assembled concentrically on the upstream and downstream sides; if the connection is improper, it will cause liquid

turbulence, thus affecting the measurement accuracy.

IMPORTANT: The washer and ground ring must also be installed concentrically.

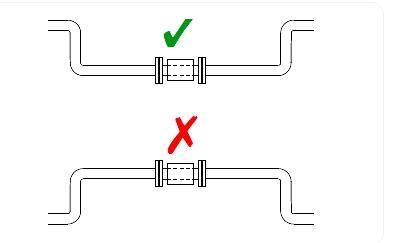

4. The

magnetic flow meter must always maintain a full pipe state. Therefore, the electromagnetic flowmeter is strictly prohibited from being installed at the highest point or free

outlet in the pipeline system. Due to the influence of gravity, the pipe may be empty or not full.

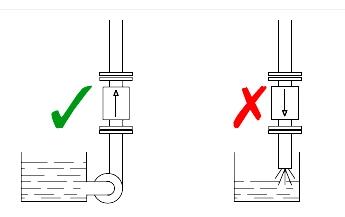

5. If the liquid being measured carries particles, such as when measuring sludge, sewage, etc., the electromagnetic flowmeter must be installed vertically and keep the flow direction

from bottom to top to ensure that the electromagnetic flowmeter is always full of pipes and can effectively reduce the occurrence of bubbles. .

If you want to know other information about

electromagnetic flowmeters, such as how to select, quote, and other installation issues, please feel free to consult CIXIFM winny:

Email:sales01@cxflowmeter.com

whatsapp:008618049841995