Liquid turbine flow meter

The

liquid turbine flow meter is a precision flow measuring instrument, which can be used to measure the flow and total amount of liquid when matched with the corresponding flow totalizer. Liquid turbine flowmeters

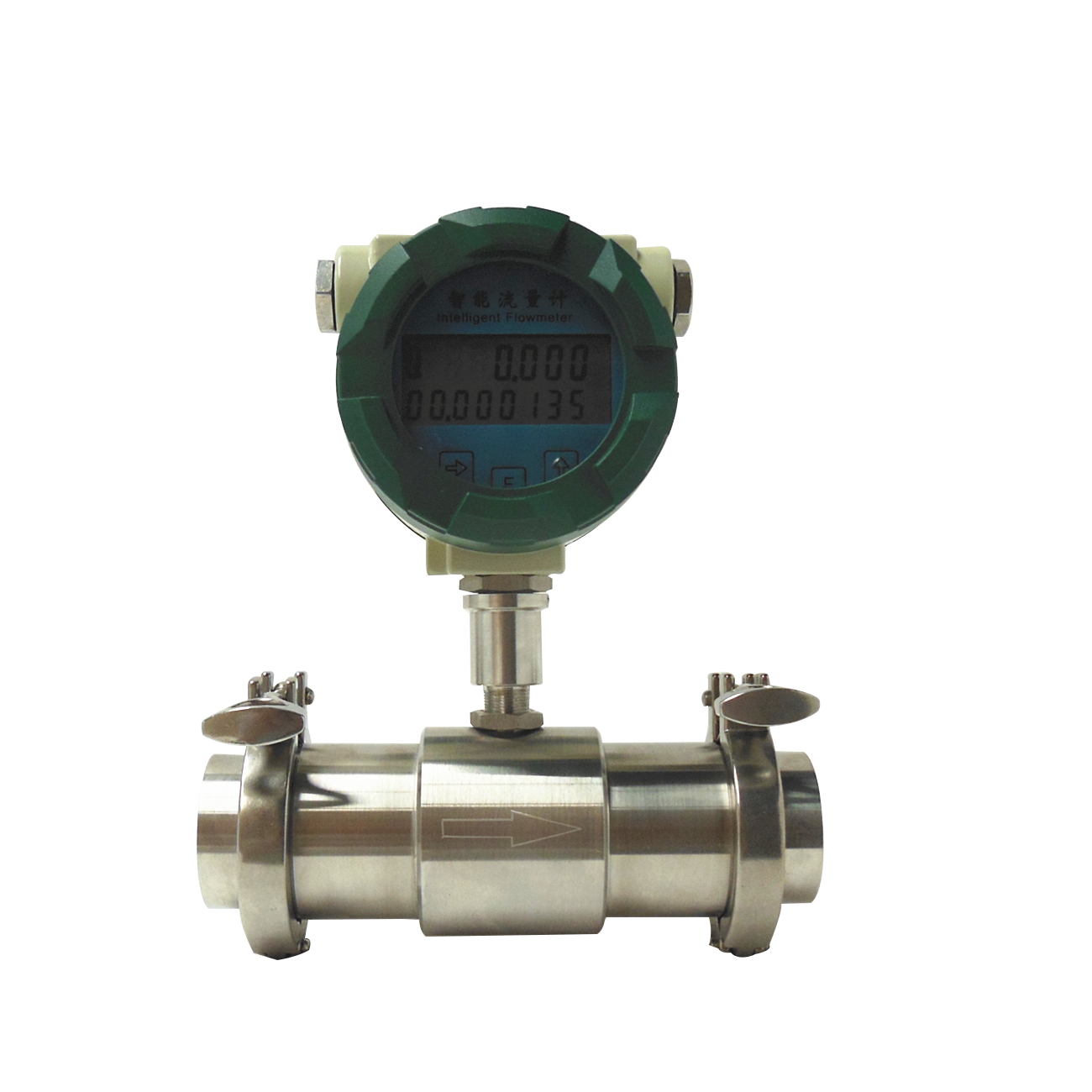

are widely used in metering and control systems in the fields of petroleum, chemical industry, metallurgy, scientific research, etc. Liquid turbine flow meters equipped with sanitary joints can be used in the pharmaceutical industry.

sales01@cxflowmeter.com

The structure of the integrated

liquid turbine flow meter is explosion-proof design, which can display the total flow rate, the instantaneous flow rate and the percentage of full flow rate. The battery adopts long-term lithium battery.

The battery life of single-function integrator can reach more than 5 years, and the battery life of multi-function indicator can reach more than 12 months.

The integrated meter head can display many flow units, including cubic meters, gallons, liters, standard cubic meters, standard liters, etc., fixed pressure and temperature parameters can be set to compensate for the gas, and

the pressure and temperature parameters do not change much. , The instrument can be used for fixed compensation accumulation

Features

n High accuracy, generally up to ±1%R, ±0.5%R, high-precision type up to ±0.2%R;

n Good repeatability, such as frequent calibration or online calibration can get extremely high accuracy, it is the preferred flow meter in trade settlement;

n Equipped with three-point correction of instrument coefficients, intelligent compensation of non-linear instrument coefficients, and can be corrected on site;

n All valid data will not be lost for 10 years after power failure;

n Wide range, medium and large diameters can reach 1:20, and small diameters are 1:10;

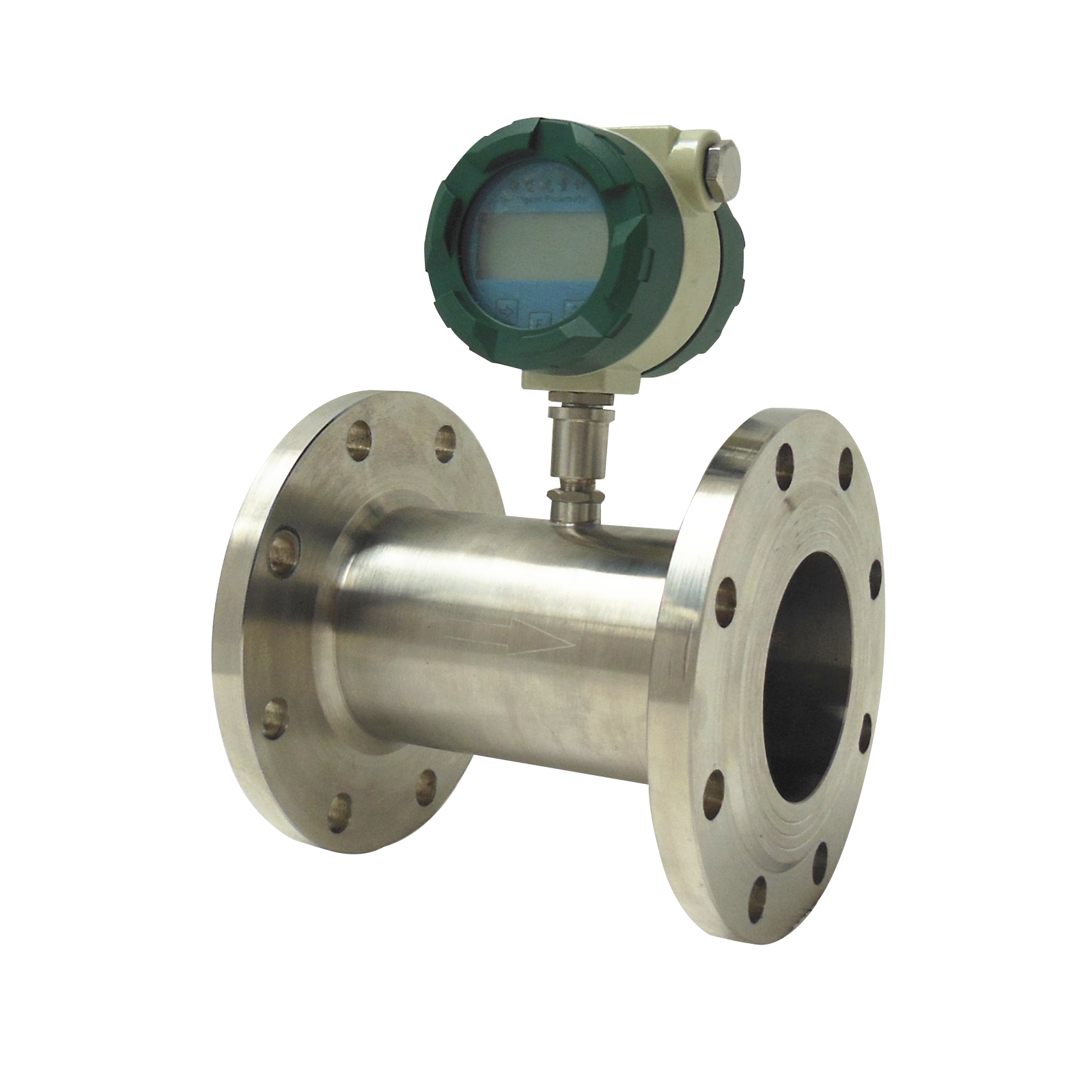

n Compact and lightweight structure, convenient installation and maintenance, and large circulation capacity;

n Suitable for high-pressure measurement, no holes are required on the meter body, and it is easy to make a high-pressure meter;

n There are many types of special sensors, which can be designed as various special sensors according to the special needs of users, such as low temperature type, two-way type, downhole type, special type for sand mixing, etc.

n It can be made into a plug-in type, suitable for large-caliber measurement, with low pressure loss, low price, continuous flow removal, easy installation and maintenance;

Classification

A turbine is placed in the center of the pipe, supported by bearings at both ends. When the fluid passes through the pipeline, it impacts the blades of the turbine flowmeter, generating a driving torque to the turbine flowmeter,

so that the turbine flowmeter overcomes the friction torque and the fluid resistance torque to generate rotation. Within a certain flow range, for a certain fluid medium viscosity, the rotational angular velocity of the

turbine flowmeter is proportional to the fluid flow rate. Thus, the fluid flow rate can be obtained from the rotational angular velocity of the turbine flowmeter, so that the fluid flow rate through the pipeline can be calculated.

The rotation speed of the turbine flowmeter is detected by a sensor coil installed outside the casing. When the turbine flowmeter blades cut the magnetic field lines generated by the permanent magnet in the casing,

it will cause the magnetic flux in the sensing coil to change. The sensing coil sends the detected magnetic flux periodic change signal to the preamplifier, amplifies and reshapes the signal, generates a pulse signal proportional

to the flow rate, and sends it to the unit conversion and flow integration circuit to obtain and display the cumulative flow value; At the same time, the pulse signal is sent to the frequency current conversion circuit,

which converts the pulse signal into an analog current quantity, and then indicates the instantaneous flow value.

Instrument type

sales01@cxflowmeter.com

A. On-site display type

This intelligent flowmeter is a new type of flowmeter display instrument designed with advanced single-chip microcomputer technology, and is matched with flow sensors (such as turbines and vortexes) that output pulse signals.

Can display instantaneous flow and cumulative total. Cumulative flow: 8 digits, 3 significant digits after the decimal point. Instantaneous flow: six digits, which can show the change per liter. Display accuracy: ±1 display unit.

Signal output: pulse output: 1~3000Hz external +12~+24VDC power supply Current output: 4~20mA external +24VDC power supply (two-wire system) built-in 2 3V lithium batteries in parallel for power supply.

When the voltage is lower than 2.7V, there will be an undervoltage indication, explosion-proof type. Small signal removal function.

B. Pulse output type

Working voltage: +12VDC or +24VDC (the customer must select a power supply before ordering). Signal transmission distance: less than 250 meters. Output signal: square wave signal amplitude: +12VDC power supply

amplitude is about 10V+24VDC power supply amplitude is about 20V Installation: the amplifier and the turbine flow sensor are connected with M16×1.5 threads, after the turbine flow sensor is installed, screw the amplifier to

On the turbine flow sensor, tighten the lock nut by hand until the amplifier feels to the end. Wiring: The pulse output amplifier has three external leads, the red wire, the white wire and the shield. The red wire is connected to the

positive power supply, and the white wire is the pulse output to connect to other displays or equipment, and the shield is grounded.

C, 4~20mA output type

Working voltage: external power supply +24VDC (two-wire system) Output signal: 4~20mA or 1-5V, 4mA corresponds to zero flow of turbine flow sensor, 20mA is the maximum flow of turbine flow sensor, and the flow range is

shown on the nameplate of turbine flow sensor. Signal transmission distance: less than 250 meters. Installation: After the turbine flow sensor is installed, screw the amplifier to the turbine flow sensor connector (m16×1.5 thread),

tighten the lock nut by hand until you feel the amplifier is in the bottom. Wiring: The external leads of the 4-20mA output amplifier are red and white wires. The red wire is the power wire, and the white wire is the signal wire.

D. Split remote display type

Working voltage: 220VAC with external power supply. Signal transmission distance: less than 250 meters. Instantaneous four digits: cumulative total nine digits. Display size: horizontal type: 160mm×80mm vertical

type: 80mm×160mm display instrument with 4~20mA output and parallel Can connect with computer

For more information, please contact winny: sales01@cxflowmeter.com