Metering Pumps For Polyurethane (PU) Working Principle

sales01@cxflowmeter.com

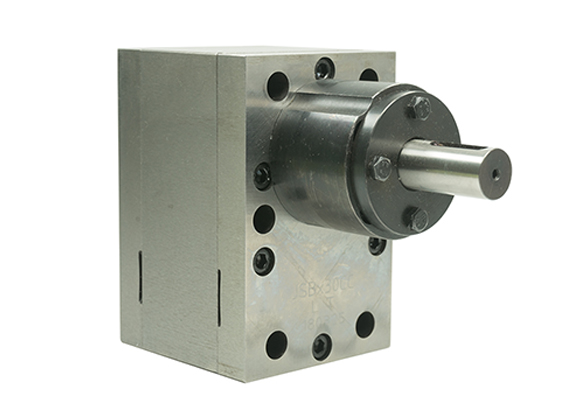

Polyurethane pouring machine is used for multi-mode continuous production of rigid semi-rigid polyurethane products and polyester elastomer products. The metering pump of polyurethane pouring machine is a metering pump for assisting polyurethane pouring machine in pouring. In the case of low resistance (pressure loss), the precise metering of a small amount of liquid can still give a sufficient number of pulses for a small amount of rotation in the case of extremely slow gear rotation.

The working principle of the

metering pump dosing pump of polyurethane pouring machine

The motor drives the worm through the coupling, and the main shaft and the eccentric wheel rotate through the worm gear deceleration, and the eccentric wheel drives the sliding adjustment seat of the bow-shaped connecting rod to reciprocate. When the plunger moves backward to the dead point, a vacuum gradually forms in the pump chamber of the polyurethane pouring machine metering pump, the suction valve opens, and the liquid is sucked in; when the plunger moves forward to the dead point, the suction valve closes, the discharge valve opens, and the liquid Discharge when the plunger moves further. The reciprocating cycle of the pump forms continuous pressure and quantitative discharge of liquid.

Selection Skills of Metering Pump for Polyurethane Pouring Machine

When selecting a metering pump for a polyurethane pouring machine, it is necessary to provide the product with the medium, displacement, viscosity, pressure, temperature, and what functions need to be achieved? Do I need a mounting plate? With servo motor inverter? Is there a PLC on site? If there are special requirements, it is necessary to discuss with the product party in advance whether it can be customized, and finally determine the selection of the polyurethane pouring machine metering pump.

range of rotation

10-200R/min

Material selection: Tool steel, 9Cr18mov, Stellite, Hastelloy

Sealing method: combined seal, stuffing seal, packing seal, mechanical seal, magnetic seal

Press force:

2-30Mpa

Medium viscosity: ≤1 million CP

Maximum temperature: common temperature ≤ 200°C, maximum temperature can be customized (450°C)

Pump body precision: back in and out, left and right in and out

If you want to know more details of

PU metering pump dosing pump, please contact winny:

sales01@cxflowmeter.com